VP Series

Vertical Machining Center

HIGH SPEED & HIGH ACCURACY!

Controllers are available for FANUC / Mitsubishi / SIEMENS

C-type Machine Structure

Through the FEM analysis to optimize machine structure and ribs distribution. For providing an stable machining precision, VP series adopts Delta structure and has outstanding force-flow design, these provide the excellent performances on cutting force resisting and smooth force transferring.

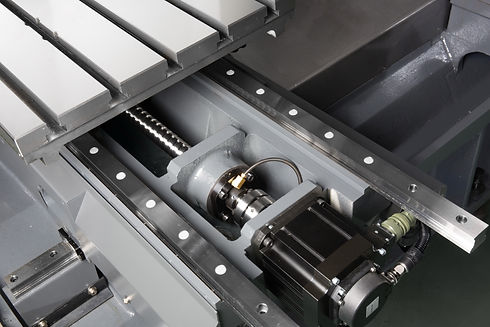

High Speed Feeding System

X/Y/Z axis adopts ballscrew and linear guideway to achieve the goal of high speed feeding and has the features of high rigidity, low friction, and low noise.

Direct-coupled Servo Motor

Servo motors are coupled directly to the ballscrews with non-backlash steel couplings, it ensures the accuracy in micro-feeding and has great torsional rigidity.

Direct-drive Spindle

Direct-drive spindle that is coupled directly to the motor provides high accuracy, high acceleration ability, low vibration, long usage life, and easy to maintain.

Spindle Cooling System

Monitor and control the machine temperature is maintained in an specific range. It limits the temperature rising in the spindle and reduces the possibility of thermal deformation.

Coolant Through Spindle (CTS)

The coolant is supplied from the end of the tool. It restrains the machining temperature and extends the usage life for the tool. Furthermore, it also benefits on chip disposal in deep hole machining.

Safety

Standard equipped with sensors in spindle draw bar for confirming the clamping situations. It avoids the machine to run under the situations of without tool or tool unclamping.

Automatic Winding Switch

The automatic high/low winding changing function allows the machine still keeps high torque output in high speed machining for better machining efficiency.

Rapid Tool Changing

-

Stable, accuracy, and high speed disc-type tool magazine

-

T-T time only 2 seconds (ISO 10791-9)

-

Tool capacity is 24 or 30 tools

Tool Capacity

-

24 tools (Standard)

-

30 tools (Option)

User-friendly Operation

Easy to process visual management and daily maintenances

Cutting Demonstration

Impressive high speed and stable machining performance

Made in Taiwan

Establised in 1969 and was listed on stock since 2003 in Taiwan. Tongtai locates in Kaohsiung and our business was started from special purpose machine manufacturing. Now, we are a leading machine tool manufacturer in Taiwan and having diverse machine types.

Products include vertical/horizontal machining centers, vertical/horizontal lathes, multi-tasking machining centers, boring & milling lathes, metal additive manufacturing equipment, PCB machine, and laser processing equipment, thus allowing us to provide a one-stop solution for any requirement. We are very experienced and capable of turnkey solutions and whole plant exports. Everything from the initial machine planning to the final machine processing can be designed and executed by Tongtai, where the customer only needs to check and accept to begin mass production.

You might also interesting

Tongtai Machine & Tool Co., Ltd.

Headquarters : No.3, Luke 3rd RD.,Luzhu Dist.,Kaohsiung City 82151, Taiwan

TEL : +886-7-976-1588 | FAX : +886-7-976-1589

COPYRIGHT © TONGTAI MACHINE & TOOL CO., LTD. ALL RIGHTS RESERVED.