歡迎蒞臨 TMTS2024台灣國際工具機展!

Welcome to TMTS2024!

東台集團是一家跨國的工具機集團,擁有六家品牌工具機廠,

分別是位於台灣的東台精機、榮田精機、譁泰精機、亞太菁英,

以及法國的PCI SCEMM與奧地利的ANGER MACHINING GmbH。

東台集團以提供客戶全方位的解決方案為核心價值。

本次展覽匯聚了東台集團的成員們,

展示包括電動車、航太、能源、生醫解決方案在內的精彩內容。

同時,我們將展出智慧製造解決方案、自動化技術、多軸加工方案、

積層製造解決方案、邊緣計算、整廠監控、數位雙胞等眾多亮點,

同時也致力於數位與綠色雙轉型,協助客戶打造未來競爭力。

歡迎下載TMTS APP 領取免費入場證,

並預約東台業務人員為您提供攤位導覽和諮詢。

非常期待您的蒞臨,我們展會現場見!

The TTGroup is a global machine tool group with six international brands:

Taiwan-based Tongtai, Honor Seiki, Quick-Tech, APEC, France-based PCI SCEMM,

and Austria-based Anger Machining GmbH.

Providing customers with total solutions is our core value.

During TMTS 2024, TTGroup will showcase various intelligent manufacturing solutions for aerospace, energy, electric vehicles, and biomedical industries.

We will also present automation technology, multi-axis machining,

additive manufacturing, factory monitoring, digital twins,

and other exciting highlights. TTGroup is committed to digital and green transformation to help customers build their competitiveness in the future.

Welcome to download the TMTS APP to get your free admission ticket.

Feel free to make a reservation with TTGroup's sales representatives for

booth tours and consultations. We look forward to your visit to the exhibition.

See you there!

產業解決方案

INDUSTRIAL SOLUTION

電動車解決方案

Electric Vehicle Solution

東台、ANGER MACHINING和PCI-SCEMM,皆在電動車零部件加工領域積累積了豐富的成功經驗,為客戶提供可靠且經濟的解決方案。

Tongtai, PCI-SCEMM andANGER MACHINING,have successful experiences in electric vehicle parts machining. We provide customers with reliable and cost-effective solutions.

航太解決方案

Aerospace Solution

亞太菁英擁有豐富的五軸航天航空應用經驗,是航太加工製程的全方位服務提供者,幫助客戶應對航太產業的成長挑戰。

APEC has rich experience in five-axis aerospace applications and serves as a comprehensive service provider for aerospace machining processes, helping customers address the growth challenges in the aerospace industry.

能源解決方案

Energy Solution

榮田精機智慧立式車床解決方案在能源產業取得領先技術成就。透過「以車代磨」技術加工軸承環,有效提升客戶加工生產效率。

Honor Seiki is dedicated to large component machining for energy industries with its intelligent vertical lathe solutions. Utilizing "Hard turning" technology for process integration of slewing bearings significantly enhances customers' production efficiency.

生醫解決方案

Medical Biotechnology Solution

譁泰精機擁有專為醫療生技產業設計的車銑複合車床,能夠在一次工序內完成高度複雜的工件,更可用於製造各種醫療相關零件,提升整體生產效率與品質。

Quicktech multi-tasking turning center is particularly suitable for the medical biotechnology industry. It is the best engineering-intensive solution for manufacturing various medical-related parts, enhancing overall production efficiency and quality.

展機資訊

Products

特色

-

東台工程集約新解決方案,可滿足少量多樣的加工需求。

-

機台剛性及穩定性良好,確保精密加工時具備良好的精度。

-

採用正交式的機械座標加工,程式編輯容易,可提高加工精度與效率。

-

中央排屑系統有效防止了積屑溫升的問題,減少環境變因,提升精度。

-

搭載APC盤面自動交換系統,減少機台停機時間。

-

機台搭載熱補償功能,透過該技術能確保在不同溫度條件下獲得理想的加工精度。

Features

-

Tongtai's new solution of process integration which will definitely meet the demands of high-mix low-volume manufacturing.

-

Excellent machine rigidity and stability to ensure high accuracy during precision machining.

-

Orthogonal mechanical coordinate system for easy programming and enhance the precision and efficiency of machining.

-

Central chip removal system effectively prevents the problem of internal temperature rise from accumulated cutting chips and reduces the environmental variables for higher precision.

-

Equipped with APC (auto pallet changer) system to shorten the machine idle time.

-

Built-in thermal compensation function to ensure ideal machining accuracy under different temperature conditions.

htt-500

臥式五軸加工中心機

5-Axis Horizontal Machining Center

特色

-

具備較小面寬優勢的同時有著大的機內加工空間。

-

搭載高轉速主軸,可滿足高效率、高精度的加工需求。

-

BBT-40直結式主軸提供高效加工剛性。

-

圓盤刀庫可任意置刀及預先選刀,搭配ATC機構可縮短非切削時間,達成高效率。

-

最佳化C型結構設計,機台剛性及穩定性良好,確保加工時具備良好的精度。

-

反覆驗證測試標準與週邊項目,提供客戶高效率、高品質、低養護 成本的產品。

Features

-

It combines the advantage of a smaller footprint with a large internal machining space.

-

Equipped with a high-speed spindle to meet the requirements of efficient and precise machining.

-

Direct-drive spindle BBT-40 provides a high rigidity and high efficiency.

-

The tool magazine allows for flexible tool placement and pre-selection, coupled with a high-speed ATC mechanism to reduce non-cutting time, showcasing efficiency similar to drilling and tapping machining centers.

-

High-quality spindle and high-rigidity structure design are subject to high standards of machine accuracy to achieve good cutting performance.

-

By Tongtai production system, we check every detail process from design, manufacturing, assembly and QC.

VP-12

立式加工中心機

Vertical Machining Center

特色

-

MT系列具有較小的占地面積、較短的週期時間以及較高的稼動率。

-

雙主軸雙刀塔整合上下料機械手的CNC車床。

-

針對需要單件自動送料加工設計的設備。

-

行程短、空切削時間短、熱變位小。

-

TiOperator讓MT系列得以輕易達成高效率24小時運轉。

Features

•Dual-spindle, dual-turret CNC lathe with an integrated loading/unloading robotic arm.

•Designed for processes that require automatic single-piece feeding.

•The MT series features a smaller footprint, shorter automation pathways, and higher productivity.

•Short travel distances, minimal idle time, and minimal thermal displacement.

•The TiOperator enables the MT series to achieve efficient 24-hour operation effortlessly.

MT-1500

雙主軸CNC車床

Dual-Spindle CNC Lathe

特色

-

靈活彈性櫛式刀具系統

-

雙主軸可做正背面同步車銑雙向加工。

-

全新B 軸角度可連續360。 斜度攻牙及鑽孔。

-

雙程式系統, 可同時運行2組程式, 工件加工時間有效減少45%。

-

擁有多達49 把刀具, 在生產少量多樣的零件時,能夠節省大量前置作業時間。

Features

•Flexible gantry type tooling system.

•Two spindles, OP1 and OP2 finish in one machine.

•Double free angel B axis 360 degrees for all the angular tapping and drilling.

•Simultaneous synchronization reduces working time and increases accuracy.

•Total 49 tools for all the flexible applications.

i42-ULTIMATE

CNC車銑複合車床

Multi-Tasking CNC Lathe

特色

-

擁有精巧的機身尺寸,佔地面積小,適用於小型精密加工的客戶。

-

一台機器即可完成銑削和車削工藝的整合,提供加工任務的流暢解決方案。

-

立式結構解決傳統車床在加工上的限制。

-

能一次完成兩種加工製成,降低工件人為介入的錯誤機率。

Features

-

The G800-T machine boasts a compact body size. This design feature enhances its suitability for small-scale precision machining.

-

It combines milling and turning processes within a single machine, and offers a streamlined solution for machining tasks.

-

Vertical Structure overcomes the constraints of traditional lathe processing.

-

It enables smoother transitions from turning to milling,eliminating the need to move the workpiece, reducing processing time and minimizing human errors.

G800-T

五軸銑車加工中心

5-Axis Milling-Turning Machining Center

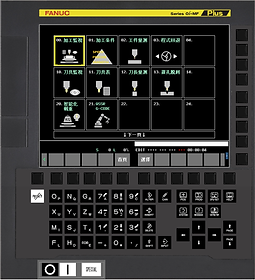

智慧軟體

Intelligent Software

領取免費入場證

Get Free Ticket